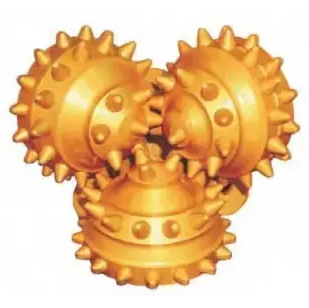

Buy Quality Tricone Rock Bits - Certified and Reliable Supplier for America and the Middle East with Low Minimum Order Requirement

Tricone Bits IADC417-637: A Revolutionary Rock Drilling ToolFor oil and gas drilling, mining, and exploration, the most essential tool is a tricone bit. These cones have three cones rotating at different speeds that cut through various rock types. Tricone bits have become a popular drilling tool because of their ability to drill through the toughest rock formations.If you need to drill through hard and deeprock formations, then Tricone Bits IADC417-637 is the perfect tool for you.What are Tricone Bits?A tricone bit is a drill bit that consists of three rolling cones. The cones are mounted on a spindle and rotate on bearings. The cutting structure of tricone bits varies depending on the application.They were introduced in the early 1930s, and since then, tricone bits have become one of the most commonly used drilling tools worldwide.What is IADC417-637?IADC stands for International Association of Drilling Contractors. It is a global organization that has set the standards for drilling tools. IADC established a classification system that categorizes tricone bits based on their cutting structure and application.IADC417-637 is a code assigned to tricone bits that are ideal for drilling through medium to hard rock formations. It is a versatile tricone bit that can be used in shallow and deep drilling applications.Why use Tricone Bits IADC417-637?Tricone Bits IADC417-637 is one of the most popular tricone bits in the oil and gas industry, mining, and exploration. The reasons behind their popularity are the following:1. Quality and CertificationThe Tricone Bits IADC417-637 is API (American Petroleum Institute) and ISO (International Organization for Standardization) certified. These certifications ensure that the tricone bits are of high quality and meet the industry's standards.2. Extreme DurabilityTricone Bits IADC417-637 is designed to withstand the toughest drilling conditions. The materials used for the cones and bearings are of high quality, which ensures that they last long.3. VersatilityTricone Bits IADC417-637 is highly versatile and can be used in a wide range of drilling applications. Whether you are drilling through hard or soft rock formations, these tricone bits will provide excellent performance.4. Wide AvailabilityKingdream API Tricone Rock Bits is one of the leading suppliers of tricone bits in America and the Middle East. They have made Tricone Bits IADC417-637 readily available for purchase in these regions.5. Minimum Order RequiredKingdream API Tricone Rock Bits has set the minimum order to one piece. This makes it easier for drilling companies, mining, and exploration to purchase Tricone Bits IADC417-637 for their operations.ConclusionTricone Bits IADC417-637 is a reliable and high-performance tricone bit that is perfect for drilling through medium to hard rock formations. Its durability, versatility, and availability make it an excellent choice for drilling applications.Moreover, with Kingdream API Tricone Rock Bits, you will never have to worry about the quality of your drilling tools. Their tricone bits are certified by industry standards to ensure that you get the best quality products.Order now and experience the power of Tricone Bits IADC417-637.

Read More

Top-rated PDC Bits for Efficient Water Well Drilling in China's Hebei Province

Did you know that China is home to some of the best water well drilling machines in the world? In fact, one of the most trusted suppliers of PDC bits for water well drilling can be found in Cangzhou, Hebei Province.Cangzhou Great PDC Bits Co., Ltd. is a leading manufacturer of PDC bits used in water well drilling machines. With advanced technology and state-of-the-art facilities, they are able to produce PDC bits that are durable, efficient, and reliable.Their PDC bits are made from premium quality materials, and are built to withstand the toughest conditions. They have a broad range of PDC bits available, each designed to meet specific drilling requirements.Their PDC bits are available in various sizes and types, and are suitable for different drilling methods. Whether you need a PDC bit for horizontal drilling or vertical drilling, they have it all.One of the key benefits of using PDC bits for water well drilling is their ability to drill deeper, faster, and more efficiently. Unlike traditional roller cone bits, which can wear out quickly and require constant maintenance, PDC bits are built to last longer and require less maintenance.This makes them not only a more cost-effective solution, but also a more environmentally friendly one. By reducing the need for excessive drilling and maintenance, PDC bits can help conserve natural resources and reduce carbon emissions.In addition to being a trusted supplier of PDC bits, Cangzhou Great PDC Bits Co., Ltd. also offers excellent customer service and support. They have a team of experienced professionals who can help you choose the right PDC bit for your drilling needs, and provide timely and efficient support should any issues arise.So if you're looking for a reliable and efficient water well drilling machine supplier, look no further than Cangzhou Great PDC Bits Co., Ltd. With their advanced technology, premium quality materials, and exceptional customer service, they are the perfect choice for all your PDC bit needs.

Read More

Shop High-Quality Back Reamers and Hole Openers - Explore a Wide Range of Options

Title: Efficient and Durable Back Reamers and Hole Openers for HDD OperationsIntroduction:Horizontal Directional Drilling (HDD) has revolutionized the underground construction industry, enabling the installation of utilities and pipelines with minimal disruption to the surface. To ensure successful HDD projects, it is crucial to utilize high-quality equipment such as back reamers and hole openers. In this blog, we will delve into the importance of these tools, their benefits, and the different options available in the market.The Significance of Back Reamers and Hole Openers in HDD:Back reamers and hole openers play a vital role in HDD operations. They are essential for enlarging the pilot hole created by the cutting head, allowing the installation of pipelines and utilities with larger diameters. These tools are specifically designed to overcome challenging ground conditions and provide optimal borehole diameter expansion.Efficiency and Durability in HDD Projects:When it comes to any HDD project, efficiency and durability are key factors. The selection of the appropriate back reamer or hole opener can contribute significantly to the overall success of the operation. There are various factors to consider for efficient and durable HDD hole opening, such as ground conditions, required borehole diameter, and the type of material being drilled.Benefits of High-Quality Back Reamers and Hole Openers:1. Optimal Borehole Enlargement: High-quality back reamers and hole openers ensure precise and consistent borehole enlargement, which is crucial for the successful installation of pipelines and utilities in deep ditches.2. Improved Efficiency: Efficient back reamers and hole openers allow for faster drilling and reduced downtime, decreasing overall project duration.3. Enhanced Safety: By utilizing reliable hole opening equipment, operators can minimize the risk of accidents, breakdowns, and unnecessary downtime.4. Cost-Effectiveness: Investing in superior back reamers and hole openers reduces the frequency of tool replacement, resulting in long-term cost savings.Different Options in the Market:While there are numerous brands available, it is important to consider the characteristics that best fit your specific project requirements. Here are a few features to look for in high-quality back reamers and hole openers:1. Robust Construction: Ensure the tools are constructed with durable materials to withstand demanding ground conditions.2. Versatility: Look for back reamers and hole openers that can function effectively in various soil types, allowing for versatility across different projects.3. Optimal Design: Consider designs that provide efficient cuttings removal, minimizing the risk of blockages and improving overall drilling performance.4. Customization: Some manufacturers offer customization options to cater to specific project needs, such as varying hole sizes and specific ground conditions.Conclusion:In the world of HDD, back reamers and hole openers play a crucial role in achieving successful borehole enlargement and installation. By investing in high-quality equipment, operators can ensure optimal efficiency, durability, and project success.At Georgia Underground Superstore, we understand the importance of reliable HDD tools. While we cannot provide specific brand information on this platform, we encourage you to contact our experienced professionals at 800-245-8339. They are always ready to assist you in finding the perfect HDD hole opener for your deep ditch project.Remember, selecting the right back reamer or hole opener is paramount for efficient and cost-effective HDD operations. Choose wisely and enjoy trouble-free drilling experiences!

Read More

How Tiny Drill Bits are Manufactured: A Fascinating Look into the Process

When it comes to manufacturing drill bits, most people typically envision larger equipment used in the oil and gas industry. However, there is a whole other world of miniature drill bit manufacturing that is equally as fascinating. In this article, we'll take a closer look at the method for producing incredibly tiny drill bits at an 8.5" pdc drill bit factory.The factory's operation is featured in a video by Science Channel's How It's Made, where it is revealed that the drill bits being produced are incredibly small and precise. These drill bits, much smaller than their larger counterparts used in oil and gas drilling, are essential tools used in the creation of small electronic devices, such as cell phones, watches, and other electronic gadgets.The drill bit manufacturing process starts with a wire that is only a fraction of the size of a human hair. This wire passes through an electrodischarge machine, which makes tiny indentations in the wire. A diamond coating is then applied to the wire using chemical vapor deposition, which ensures that the drill bit is strong and durable enough to withstand frequent use.Next, the wire is threaded through a special drilling machine called a Swiss-style lathe. This lathe is incredibly precise and can drill holes smaller than 0.01 inches in diameter. The drill bit is then cut from the wire at the appropriate length.After the drilling process, the drill bits are measured to ensure that they meet the factory's strict quality control standards. Any drill bits that don't meet these standards are rejected and recycled.Finally, the completed drill bits are packaged and prepared for shipping to various electronics manufacturers around the world. These drill bits are often used in the production of tiny electronic components that require precise and accurate drilling.In conclusion, the process of manufacturing miniaturized drill bits is a complex and intricate process that requires a high degree of precision and accuracy. The 8.5" PDC drill bit factory featured in the How It's Made video provides some insight into the rigorous methods that are used to create these tiny tools. The result is an incredibly durable and reliable product that is essential in the production of small electronic devices.

Read More

Popular 6-Inch Tricone Bit for Directional Drilling: Metal Seal and Elastomer Seal Bearings Available

Read More

6-inch Milled Tooth Tricone Drill Bit for Oilfield Drilling – Efficient Drilling Solution

Read More

SEO Title: High-performance 9" Tricone Bit for Enhanced Drilling Operations

Title: Innovative IADC347 9" Tricone Bit Sets New Standards in Drilling EfficiencyIntroduction:In the ever-evolving field of drilling technology, efficiency and reliability are crucial factors that can significantly impact the success of any project. One company, an industry leader in the design and production of drilling solutions, has revolutionized the drilling sector with the introduction of their newest product - the IADC347 9" tricone bit. With its cutting-edge engineering and exceptional performance, this state-of-the-art tricone bit is making its mark as a game-changer in the field of drilling operations.Paragraph 1:{Company Name}, an established and highly renowned provider of drilling equipment, has consistently strived to deliver innovative solutions that enhance efficiency and productivity. Building upon years of experience and expertise in the drilling industry, the company has unveiled their latest creation, the IADC347 9" tricone bit. Designed to meet the evolving challenges of modern drilling operations, this cutting-edge tool is garnering attention for its exceptional performance and advanced features.Paragraph 2:At the heart of the IADC347 9" tricone bit is its innovative design, which seamlessly combines strength and reliability with exceptional drilling efficiency. Crafted using premium-quality materials, this product guarantees extended durability, reducing downtime and maintenance costs for drilling operations. The tricone bit's unique configuration and precision engineering allow for smooth drilling operations across a wide range of geological formations, enhancing productivity, and minimizing risks.Paragraph 3:One of the key features that sets the IADC347 9" tricone bit apart from its competitors is the incorporation of superior bearing technology. By integrating state-of-the-art sealed bearing systems, the tricone bit demonstrates enhanced bearing life, reducing the need for frequent replacements. Reduced deflection during drilling allows for more precise and accurate drilling operations, resulting in increased overall performance and cost-effectiveness.Paragraph 4:Furthermore, the IADC347 9" tricone bit boasts an advanced cutting structure that is specifically designed to maximize drilling efficiency. The combination of carefully selected carbide inserts and premium diamonds ensures optimal performance, even in harsh drilling environments characterized by abrasive formations. This cutting structure enhances drilling speed, reduces wear and tear, and provides significant cost savings to drilling contractors.Paragraph 5:As technology continues to advance, the IADC347 9" tricone bit demonstrates its forward-thinking approach by being fully compatible with various drilling systems. This versatility allows drilling contractors to easily adapt to different drilling operations, while maintaining exceptional drilling performance. The tricone bit's compatibility with multiple systems minimizes downtime, simplifies logistics, and increases operational flexibility, appealing to contractors operating in diverse drilling environments.Paragraph 6:In addition to its operational advantages, the IADC347 9" tricone bit places a strong emphasis on safety, a critical aspect in drilling operations. The tricone bit's design includes features that reduce vibrations, leading to enhanced operator comfort and reduced fatigue. This ultimately contributes to safer and more productive drilling operations for the entire team.Conclusion:{Company Name}'s introduction of the IADC347 9" tricone bit signifies a significant technological advancement in the drilling industry. With its innovative design, superior bearing technology, advanced cutting structure, and unparalleled versatility, this tricone bit sets new standards for drilling efficiency and demonstrates the company's commitment to meeting the evolving needs of the industry. As drilling contractors increasingly seek safer and more productive solutions, the IADC347 9" tricone bit proves to be a game-changer, enabling enhanced performance and significant cost savings in drilling operations.

Read More

7 1/2 TCI Tricone Bit for Water and Petroleum Well Drilling - IADC517 Standard

TCI petroleum tricone bit is an important tool in petroleum and water well drilling operations. It is designed to handle a wide range of geological formations with varying degrees of hardness. The tricone bit is a three-cone drill bit with Tungsten Carbide Inserts (TCI) on each cone. These inserts are made of hard, wear-resistant Tungsten Carbide, which can withstand extreme drilling conditions and high temperatures.The API 7 1/2 IADC517 TCI Tricone Bit is a specially designed tricone bit that is ideal for drilling in rock formations that have high compressive strength. This tricone bit has been designed to operate in a variety of drilling conditions and can be used for both petroleum and water well drilling. It is made from high-quality materials, making it highly durable and long-lasting.One of the key advantages of using a TCI petroleum tricone bit is that it can drill through almost any rock formation. This is because Tungsten Carbide is highly resistant to wear and tear, and can handle high compressive loads. This makes it ideal for drilling in hard rock formations, which can be difficult to penetrate using other types of drill bits.In addition to high compressive strength, the API 7 1/2 IADC517 TCI Tricone Bit is also designed to handle high temperatures. This is important, as drilling operations can generate a lot of heat, which can damage the drill bit. However, the TCI inserts are capable of withstanding high temperatures, ensuring that the drill bit remains operational even in extreme conditions.Another advantage of using a TCI petroleum tricone bit is that it is highly accurate. The three cones of the tricone bit work together to create a smooth, consistent drill pattern, which helps to reduce the risk of deviation or deviation during drilling operations. This is especially important in petroleum and water well drilling operations, where accuracy is crucial to ensuring the success of the project.Overall, the API 7 1/2 IADC517 TCI Tricone Bit is an excellent choice for petroleum and water well drilling operations. It is highly durable, long-lasting, and can handle a wide range of geological formations. With its ability to withstand high compressive loads and temperatures, it is a tool that is built to last. If you are looking for a reliable and effective tricone bit for your drilling operations, the TCI petroleum tricone bit is an excellent choice that will give you great results every time.

Read More

High-Quality Tricone Drill Bits with API Thread Connections for IADC537 and IADC637

Are you in search of top-quality tricone drill bits for your oil and gas drilling operations? Do you want a drill bit that will not only effectively cut through rock formations but also provide a long-lasting service? Look no further than the IADC537 and IADC637 TCI drag drill bits from our esteemed manufacturers and exporters.Our IADC537 and IADC637 TCI drag drill bits are perfect for a wide range of drilling operations. These bits are designed with a tri-cone structure that features carbide inserts, making them ideal for drilling through the toughest rock formations. The carbide inserts are durable and can withstand high temperatures, ensuring that the bit delivers a long service life.One of the main advantages of these tricone drill bits is their versatility, which makes them suitable for both soft and hard rock formations. The IADC537 and IADC637 bits are optimized for medium to hard formations, including limestone, dolomite, and sandstone. Additionally, these bits are available in various sizes to meet the specific needs of your drilling project.Our IADC537 and IADC637 TCI drag drill bits come equipped with API thread connections that make them easy to install and remove, maximizing your operational efficiency. These tricone bits are also designed to provide a smooth drilling experience, helping to reduce wear and tear on your equipment. You'll appreciate the effort we've put into these products to improve your drilling operations.At our manufacturing plant, quality is our top priority. Our experienced teams of engineers and technicians use advanced manufacturing processes to ensure our products meet the highest standards in the industry. This includes conducting rigorous testing procedures to ensure our products are free from defects and meet the expected levels of quality and performance.The IADC537 and IADC637 TCI drag drill bits are the perfect choices for any drilling operation. Our products are also backed by our excellent customer service team, who are ready and willing to help you with any queries or concerns you may have.To summarize, the IADC537 and IADC637 TCI drag drill bits are a top choice for anyone looking for high-quality tricone drill bits. These bits are designed to last and perform well, even in the toughest drilling conditions. With their durability, versatility, and smooth operation, these bits are sure to exceed your expectations. Try our products today and experience the difference.

Read More

Top-Quality Matrix Body PDC Bits with IADC Code for Efficient Drilling Operations

PDC Bits: The Ultimate Solution for Efficient Drilling OperationsWhen it comes to drilling operations, the quality of the drill bit used determines the efficiency of the process. With the increasing demand for hydrocarbons and minerals, there is a need for high-performance drilling solutions that can handle different formations and conditions. This is where PDC (Polycrystalline Diamond Compact) drill bits come in.PDC bits are designed to provide efficient penetration rates, longer bit life, and reduced downtime during drilling operations. The technology behind PDC bits involves layering polycrystalline diamond onto a tungsten carbide substrate, creating a super-hard and wear-resistant cutting surface.Besides, PDC bits are engineered to withstand high torque, high temperatures, and abrasive formations, making them suitable for a wide range of drilling applications. Whether drilling in hard rock, shale, sandstone, or clay, PDC bits deliver exceptional performance and improved drilling economics.Features of PDC Bits1. Matrix body PDC bitsMatrix body PDC bits are designed with a tungsten carbide matrix for enhanced durability and impact resistance. The bits are suitable for drilling in medium to hard formations and are versatile enough for different drilling applications.2. Steel body PDC bitsSteel body PDC bits are designed with high-quality steel for superior strength and durability. The bits are suitable for drilling in soft to medium formations, from shallow to deep wells.3. IADC code pdc bitsPDC bits are classified based on the IADC (International Association of Drilling Contractors) code, which provides a standard for selecting suitable bits for different drilling applications. The code considers factors such as formation type, bit type, and hydraulic horsepower to determine the optimal bit for a particular application.Benefits of PDC Bits1. Improved penetration ratesPDC bits are designed with multiple cutting elements that provide faster penetration rates than traditional drill bits. The bits are designed to drill efficiently through different formations, reducing drilling time and the associated costs.2. Longer lifespanPDC bits have a longer lifespan compared to traditional drill bits. The polycrystalline diamond cutting elements are super-hard and resistant to wear, ensuring that the bits maintain consistent performance over long hours of drilling.3. Reduced downtimePDC bits are designed to withstand high-temperature and high-pressure conditions, reducing the need for frequent bit changes. This means less downtime and improved productivity during drilling operations.4. VersatilityPDC bits are versatile enough for different drilling applications, from oil and gas exploration to mining operations. The bits can drill efficiently through various formations, including hard and abrasive rock, shale, sandstone, and clay.Pdcbits: The Supplier of Quality PDC BitsPDC bits are a vital component of any drilling operation, and selecting the right supplier can impact the quality and efficiency of your drilling operations. At Pdcbits, we pride ourselves on providing high-quality PDC bits that meet the needs of our customers.Our PDC bits are designed and manufactured to exceed industry standards, ensuring exceptional performance and longevity. We offer a wide range of PDC bits, including matrix body PDC bits, steel body PDC bits, and IADC code PDC bits, suitable for different drilling applications.Our commitment to quality extends to our customer service. We provide reliable and responsive support, from product selection to after-sales support and maintenance. Our goal is to ensure that our customers' drilling operations are efficient, cost-effective, and safe.Pdcbits: Affordable PDC Bits PricelistAt Pdcbits, we understand that cost is an essential factor when choosing PDC bits. That's why we offer affordable prices for our high-quality PDC bits. We provide a pricelist for our PDC bits, making it easy for our customers to choose the best bit for their drilling operations.In conclusion, PDC bits are a game-changer in the drilling industry, offering superior performance, longevity, and versatility. With Pdcbits as your supplier, you can be assured of high-quality PDC bits that meet your drilling needs and budget. Contact us today for more information on our PDC bits and pricing.

Read More