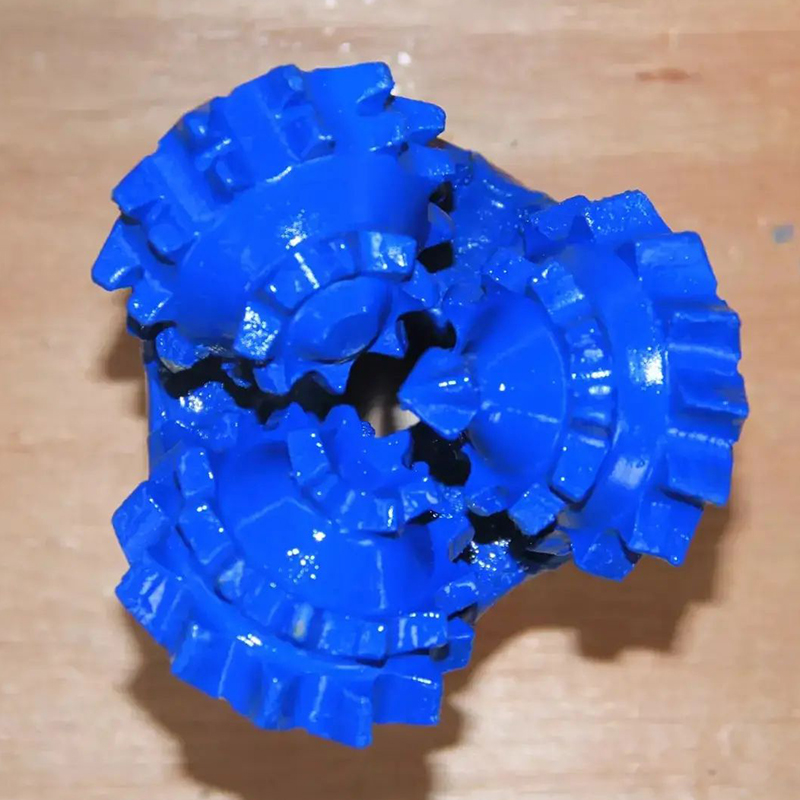

Wholesale 98mm PDC Drag Bit 3 Blades For Hard Rock Drilling Water Well in the stock from China supplier.

-

- With 3 blades

- Plane PDC cutter

- threading inside

- OEM orders are welcome

- 3, 4, 5 or 6 wings are available

- DC bit/ PDC concave drill bit/ PDC arc pillar bit/ PDC blade bit /PDC drag bit /PDC core drill bit/ PDC core drill bit

- Diameter: 60, 65, 75, 94, 113, 133, 153 and 190mm

- Used for geology exploration hole, gas drainage hole and emissions hole

- PDC bit consist of PDC cutter brazed to matrix or steel body

- The PDC cutter has high hardness, abrasion resistance and toughness, provides a cutting structure for the rock formations that respond well to failure by shearing and wears by micro-chipping

- Compare to tungsten carbide bit, cone bit, diamond impregnated bit, the PDC bit has increased efficiency and longer lifespan

- Applied to drilling soft and medium hard formation

- Product description:

- PDC non-core bit mainly used for drilling soft and medium formation and used for the purpose of geology, coalfield, metallurgy, building, mining, projectsurvey, rail, bridges and housing

- Application: used to penetrate the degassing hole, drain hole and grouting hole of coal mine or for the purpose of geology, coalfield, metallurgy, building, mining, project survey, rail, bridges and housing

- Introduction of PDC (polycrystalline diamond compact)

- PDC is made of diamond micro-powder and hard tungsten carbide under high temperature and high pressure

- It possess of high wear resistance like diamond, at the same time the impact resistance like tungsten carbide and that’s made it the best material as a drill bit cutter

- Reinforced PDC has higher dense diamond powder, claw tungsten carbide substrate made the two layers solid as whole one

- So, the reinforced PDC of supper wear resistance, longer service lifespan and high-efficiency

- Characteristics: compared with the others, this one has a higher abradability and wide range of application (rock formation application)

| Drag Bit Size(Inch) | 98mm |

| Drag Bit Connection | 2 3/8 reg pin |

| Blades Quantity | 3 |

| Drag Bit Formation | Soft ,medium soft ,hard,medium hard,very hard formation. |

| Type | Dimension | Thread Connection | |

| inch | mm | ||

| 3 blades Step Type | 3 1/2~17 1/2 | 89~445 | N Rod,2 3/8 ~ 6 5/8 API REG / IF |

| 3 blades Chevron Type | 3 1/2~8 | 89~203 | N Rod,2 3/8 ~ 4 1/2 API REG / IF |