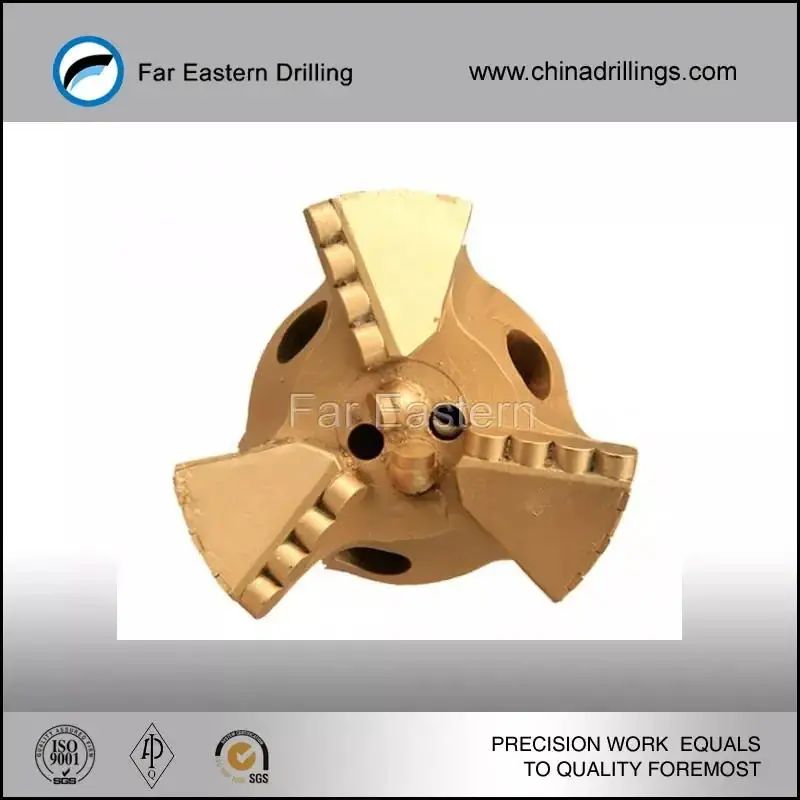

Wholesale API rotating head for petroleum drilling rig in stock with discounted price from China factory IADC: 215 is for medium to medium hard formations with high compressive strength.It is steel tooth sealed roller bearing bit with gauge protection. The ground details is for soft,unstratified,poorly compacted rocks ,including sand stones,marl limestones, poorly compacteds clays,gypsum,salts and hard coals. The tricone bit is an important drilling tools.The function of tricone roller bit has impacting,crushing and shearing and bearking the stratum rock when the roller cones rotates.Therefore,the tricone roller bit can adapt to various soft,medium and hard stratums.

Wholesale API rotating head for petroleum drilling rig in stock with discounted price from China factory IADC: 215 is for medium to medium hard formations with high compressive strength.It is steel tooth sealed roller bearing bit with gauge protection. The ground details is for soft,unstratified,poorly compacted rocks ,including sand stones,marl limestones, poorly compacteds clays,gypsum,salts and hard coals. The tricone bit is an important drilling tools.The function of tricone roller bit has impacting,crushing and shearing and bearking the stratum rock when the roller cones rotates.Therefore,the tricone roller bit can adapt to various soft,medium and hard stratums.

| Basical Specification | |

| Size of Rock Bit | 12 1/4 inches |

| 311.20 mm | |

| Bit Type | Steel Teeth Tricone Bit / Milled Teeth Tricone Bit |

| Thread Connection | 6 5/8 API REG PIN |

| IADC Code | IADC215G |

| Bearing Type | Journal Bearing |

| Bearing Seal | Elastomer sealed or Rubber sealed |

| Heel Protection | Available |

| Shirttail Protection | Available |

| Circulation Type | Mud Circulation |

| Drilling Condition | Rotary drilling,high temp drilling,deep drilling,motor drilling |

| Total Teeth Count | 135 |

| Gage Row Teeth Count | 38 |

| Number of Gage Rows | 3 |

| Number of Inner Rows | 6 |

| Jounal Angle | 33° |

| Offset | 9.5 |

| Operating Parameters | |

| WOB (Weight On Bit) | 17,527-48,985 lbs |

| 78-218KN | |

| RPM(r/min) | 300~60 |

| Recommended upper torque | 37.93KN.M-43.3KN.M |

| Formation | Medium to medium hard formation of high crushing resistance. |

12 1/4" is 311.1mm, we often call 311mm.It is normal size for the oilwell rock drilling project.This size tirocne bit will be used for small capacity of drilling rigs and it widely used in the world. It is important to choose the correct size and type of tricone bit during the drilling job.Rocks hardness are different, it maybe soft,medium ,hard or very hard.Hardness is not different even one same type of rocks,such as limestone,shale and sandstone is soft limestone,medium limestone and hard limestone,medium snadstone and hard sandstone. So please tell us full specific conditions, such as rock's hardness,type of drilling rig, ROP(rotary speed),WOB(Weight of bit) and toque.It will be big help to know the suitable bits if you can tell us vertical well drilling or horizontal drilling ,oil well drilling or no-dig drilling or foundation piling.

12 1/4" is 311.1mm, we often call 311mm.It is normal size for the oilwell rock drilling project.This size tirocne bit will be used for small capacity of drilling rigs and it widely used in the world. It is important to choose the correct size and type of tricone bit during the drilling job.Rocks hardness are different, it maybe soft,medium ,hard or very hard.Hardness is not different even one same type of rocks,such as limestone,shale and sandstone is soft limestone,medium limestone and hard limestone,medium snadstone and hard sandstone. So please tell us full specific conditions, such as rock's hardness,type of drilling rig, ROP(rotary speed),WOB(Weight of bit) and toque.It will be big help to know the suitable bits if you can tell us vertical well drilling or horizontal drilling ,oil well drilling or no-dig drilling or foundation piling.